+86 137 5010 5351

EN

EN

About Brightstar

Brightstar Prototype CNC Co., LTD has been rooted in Guangdong, China since 2009. When we set our sights on becoming a leader in the rapid prototype industry, we began to believed that "quality builds long-term trust". Over the past decade, we have gathered substantial practical expertise, earning a strong reputation for precision machining and constant recognition from clients around the world.

Efficiency & Cost Savings To Our Customers

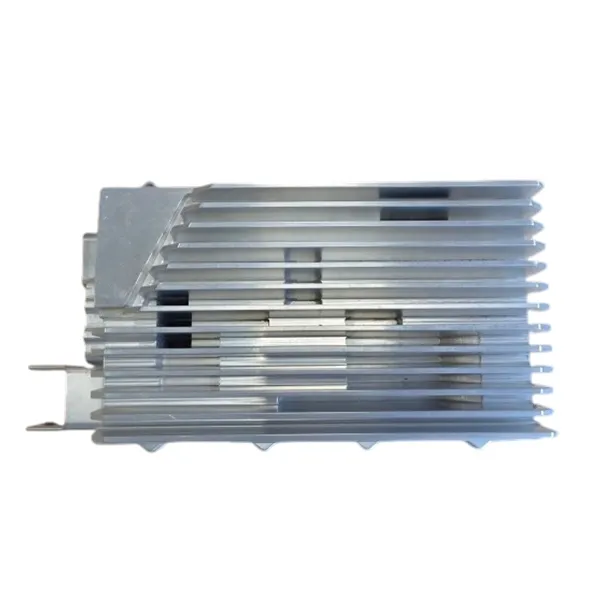

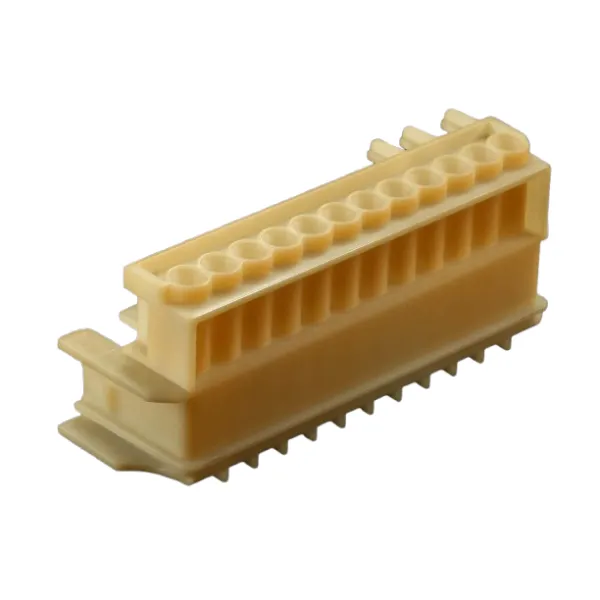

In response to the growing demand for high-precision, high-volume production with tight tolerances, complex structures, and fine surface, we invested heavily in German 5-axis CNC technology and built a specialized technical team. This enabled a successful upgrade from 3-axis to precision 5-axis machining. It provides better solutions for customers in high-end fields such as mechanical engineering, automobiles, aerospace, energy, and electronics.

Our Advantages

Technical Strength

Equipped with internationally leading CNC machining centers ( DMG, JFANUC), supporting 3-axis / 5-axis machining with an accuracy of ±0.005mm, meeting the machining needs of complex curved surfaces and precision parts.

End-to-End Process Service

Process multi-material parts such as aluminum alloy, stainless steel, titanium alloy, engineering plastics and carbon fiber; cover the entire process from milling, turning, boring to grinding; and realize one-stop delivery from prototype to mass production.

Strict Compliance with ISO 9001 Quality System

We strictly adhering to the ISO 9001 Quality Management System. From raw material selection to final inspection, every step is guided by quality standards.

Small Quantity, Fast Response

Support 24-hour rapid prototyping (simple parts), 4-7 days to deliver prototype parts to meet the urgent needs during the R&D stage. The average delivery time of small batch orders (50-500 pieces) is 20% faster than the industry standard.

Large-scale Cost Optimization

Through modular production, tool life management, centralized procurement bargaining and other strategies, the cost of mass orders (≥1000 pieces) can be reduced by 15%-25%, ensuring stable production capacity and delivery rate.

Full-cycle Customer Service

Provide technical consultation → drawing optimization → process planning → logistics distribution full process butler service, equipped with exclusive project team to synchronize progress in real time, 7×12 hours online Q&A.

Focusing on Application Scenarios

We specialize in providing in-depth CNC machining services based on the actual application scenarios of our customers' products and the performance requirements of various industries.

Targeted Industry Solutions

Brightstar has developed sophisticated, specialized machining solutions to meet the unique requirements of various industries, eliminating the performance deficiencies and costly problems associated with general-purpose processes.

Quality Guarantee

✅All-round quality control: From raw material procurement to FAI, IPQC, OQC, and a full-size inspection report to ensure the parts satisfied the international standard.

✅Complete testing equipment: Zeiss CMM, projector, spectrum analyzer, etc.

✅ Full participation in quality: Regularly carry out quality management training to improve the quality awareness and skills of all employees.

Delivering Innovative Manufacturing Solutions

· Provide customers with practical solutions to assist them quickly verify designs and optimize product performance.

· Customized parts help customers to realize complex design concepts and promote technological innovation in the engineering industry.

Quick response and Dlivery

· Support online quotation to simplify the customer's design upload & quotation process.

· Efficient & flexible production management, achieving the fastest delivery in 4 days. Global transportation company cooperate.

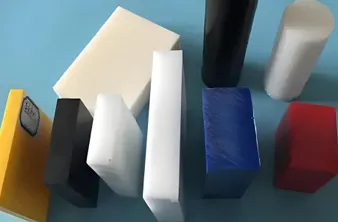

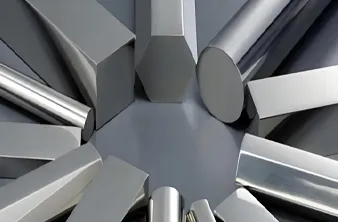

Wide range of material selection

· Metal materials: steel, stainless steel, aluminum alloy, copper, etc.

· Plastic materials: PP, Nylon, POM, PTFE, etc.

Our Partners

On Demand Manufacturing Service by Brightstar

Let’s connect today to start your production journey